National Defense Contractor Northrop Grumman announced that its Microelectronics Center will open other aerospace and national defense enterprises from now on, allowing the use of its three US government-certified semiconductor manufacturing and pac...

National Defense Contractor Northrop Grumman announced that its Microelectronics Center will open other aerospace and national defense enterprises from now on, allowing the use of its three US government-certified semiconductor manufacturing and packaging testing facilities. Media reports are to expand the safe production of local anti-microelectronic products in the United States and strengthen the American semiconductor industry and supply chain.

Norsrop Gruman is one of several national defense companies that produce and package chips in the United States. Microchips have dual uses and not only support the basic foundation of the US defense industry, but also are suitable for large-scale commercial use. Vern Boyle, vice president of Nosrop Grumanman Microelectronics Center, said that the partnership has opened up its national defense manufacturing facilities, and Nosrop Gruman has expanded and strengthened the stability of the US semiconductor industry and supply chain. It also provides partners with unprecedented opportunities to design and develop local chips, and directly purchase products from us, strengthening the entire national defense industry basic cooperation.

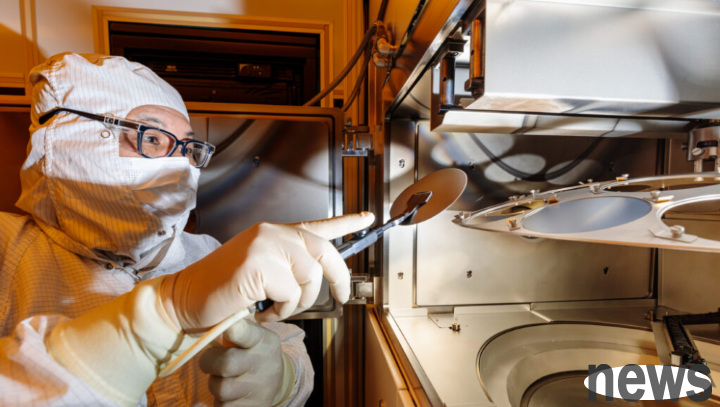

Currently, the Microelectronic Center under Nosrop Gruman has three key chip manufacturing and packaging facilities in the United States that have passed government-certified facilities. One of the crystalline factories in Maryland also has packaging testing equipment that can conduct chip production and packaging testing. Another wafer factory located in California is responsible for the manufacturing of related wafers. The last factory in Florida is mainly based on Micro-Line and packaging testing. Therefore, this new open business model allows a wide range of external customers to manufacture, package and test microelectronic products in the United States, whether for commercial purposes or for national defense applications.

As for these Nosrop are allowed. External customer identities of Gluman Facilities include American business enterprises, aerospace and defense companies, U.S. government agencies, academic units, federally-funded research and development centers, and other recognized physical or corporate units. Through this model, these partners will be able to use end-to-end advanced packaging facilities in the United States to cover reliable semiconductor design, manufacturing, assembly, and testing services for current and future generations of technology. In addition, external customers can also directly purchase semiconductor products and components produced by Nosrop Gruman through the online store.

What is particularly worthy of attention is its advanced packaging ability, Nosrop. Gruman said the company's packaging facilities have the ability to install 6-inch to 12-inch wafer bumping, probing and dicing. According to industry research, 98% of advanced packaging demand in the United States is currently sent overseas, which has put risks to the U.S. military industry and even the general scientific and technological industry. Therefore, Nosrop Gruman is a few national defense companies that can carry out chip packaging in the United States, which has important strategic significance for reducing supply chain risks.

This policy and practice is not only an innovation in the business model of Nosrop Gruman, but also represents part of the US's strategic adjustment in the global science and technology and national defense competition. For example, by building and opening up local credible manufacturing capabilities, the United States can reduce the dependence of foreign supply chains (especially potential opponents) and improve the resistance of national defense and technology systems during the period of local political or trade wars. Also, as a large defense contractor of Nosrop Gruman, if its manufacturing facilities are cooperated externally, it will benefit small and medium-sized aerospace/defense companies or supply chains and downstream companies. This can promote the ecological development and innovation of the entire industry.

In addition, Nosrop Gruman is a model that closely cooperates with chip law manufacturers and trusted manufacturing systems. If the results are good, the government may further release funds and modify laws to support more models similar to opening and cooperation. Even if the United States' alliances and partner countries want to strengthen their joint defense and technical autonomy in the fields of aerospace and defense, they may also cooperate with enterprises like Nosrop Gruman. Such supply chain transparency and credibility products are also more beneficial to international contracts.